What I Learned From Visiting The TaylorMade Ball Plant

I flew out to Liberty, South Carolina to find out how TaylorMade makes its golf balls and what I saw blew my mind

Subscribe to the Golf Monthly newsletter to stay up to date with all the latest tour news, equipment news, reviews, head-to-heads and buyer’s guides from our team of experienced experts.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered daily

Daily Newsletter

Sign up for all the latest tour news, gear reviews, head-to-heads and buyer’s guides plus features, tips from our top 50 coaches and rules advice from our expert team.

Once a week

Kick Point

Sign up to our free Kick Point newsletter, filled with the latest gear reviews and expert advice as well as the best deals we spot each week.

Once a week

Women's Golf Edit

Sign up to our free newsletter, filled with news, features, tips and best buys surrounding the world of women’s golf. If you’re a female golfer, you won’t want to miss out!

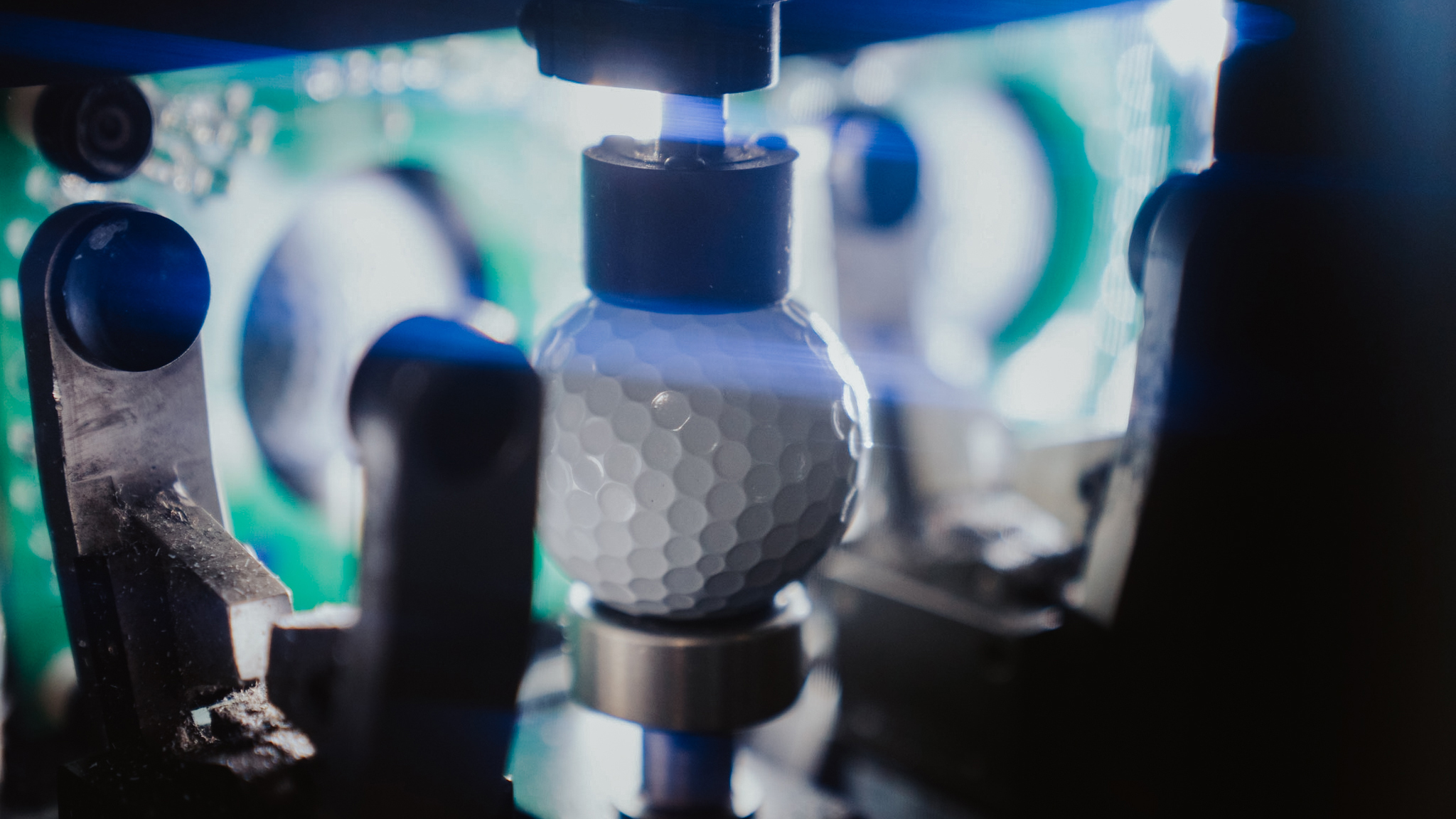

Historically, when I have thought of TaylorMade Golf, my mind has gone straight to some of the best drivers and best fairway woods in the game. Despite TaylorMade still making some of the top products in that area, in recent times I have seen more and more of TaylorMade golf balls, to the point that I have gamed the TP5x for some time now. So when I was recently fortunate enough to be invited out to Liberty, South Carolina, to the TaylorMade golf ball manufacturing plant, I was only too eager to see what was behind the doors! Here’s what I learned…

Watch: Behind the scenes tour of the TaylorMade Ball Plant in Liberty, South Carolina

TaylorMade REALLY cares about its golf balls

Make no mistake about it, TaylorMade is heavily committed to becoming the market leader in the golf ball category and it is in a big old hurry to do so. It has invested heavily in some of the most cutting-edge machinery and technology to provide the best possible product to the consumer market.

Mike Fox, Senior Category Director - Golf Balls, says “The single most impressive thing to me every time I come to the Liberty, South Carolina Ball Plant, is that golf balls don’t cost more. Every time I look at the machinery, the equipment, the people, the materials, the quality assurance, the visual tech, the amount of money that’s put into the products we’re producing to make sure that everything is perfect from a performance standpoint, a durability and quality standpoint, and now from a visual perspective as well, I can’t believe they don’t cost more than they do.”

Visual Technology is huge for TaylorMade

Whether it is Pix, Stripe, MySymbol, or even the newly introduced Ink technology on the SpeedSoft ball, TaylorMade believes that there is more to a golf ball than simply a core, inner layers and a cover. It has put millions of dollars into research and development around the visual technology of golf balls, some of which I can talk about, and some of which must remain confidential. The ability to customize your golf ball isn’t just functional, it is also a really cool way of putting some personality and expression into your golf equipment through outlets like the MySymbol program.

As Matt Nuthals, Senior Manager, Media and Partnerships, says: “The coolest thing about our visual technology, and the coolest part about some of the personalization aspects, is that we are giving golfers an added benefit to the amazing performance of the product itself. Whether you wanna personalize this from a color, from a team, or an alignment or functional standpoint, there is a visual technology for every golfer on the planet.”

I was fortunate enough to see some incredibly impressive machinery that has revolutionized golf ball printing, but understandably TaylorMade is very protective of it, so I can’t talk about it. Suffice to say, however, the MySymbol program looks like just the beginning of things to come…

Subscribe to the Golf Monthly newsletter to stay up to date with all the latest tour news, equipment news, reviews, head-to-heads and buyer’s guides from our team of experienced experts.

The Tour Balls are no different than the consumer ball

There, I said it. For all you conspiracy theorists out there, I have seen it with my own eyes. The exact same TP5 and TP5x balls that you purchase in stores around the world go through the same manufacturing process that Rory McIlroy’s and Nelly Korda’s do. They come off the same production line as your ball, go through the same finishing process, and even the same printing process. And now, with MySymbol, you can get just about the same customisation options as the tour pros!

There is a tangible improvement in this year's TP5x

I test a lot of golf equipment, and sometimes it can become a little repetitive. You can go through short periods where you feel like you are just testing a re-hashed variation of the same product. Not so with the 2024 TaylorMade TP5x golf ball. This is a genuinely much-improved product in every conceivable way. I’ve tested it thoroughly and my ball speed is up almost 3 mph throughout the bag, which is great news on its own, but it also somehow feels softer. You can read more about the details in my full review, but essentially the new ‘Speed Wrapped Core’ is much softer in its original state than previous iterations which according to TaylorMade, allows it to be made harder and faster while also providing a softer feel and better acoustic.

The TP5 benefits from the same technology also, but the TP5x is my gamer so it excites me a little more - it's unquestionably one of the best premium balls on the market this year and a genuine rival to the Pro V1x ball.

There is more to making golf balls than I realized

After sitting through a number of product presentations, interviewing several experts, and being given a full, comprehensive tour of the facility and processes involved in TaylorMade’s golf ball creation, I can safely say that I was blown away by the level of precision and detail. Every single step is meticulously controlled and checked to ensure consistency and quality. The factory runs like clockwork and the end results are very impressive.

TaylorMade seems wholeheartedly committed to making the best golf balls it can and really making waves in the category. With the lengths they are going to to do so, it wouldn’t surprise me if the market share looks very different in the next two to three years.

Joe has worked in the golf industry for nearly 20 years in a variety of roles. After a successful amateur career being involved in England squads at every age group, Joe completed his PGA degree qualification in 2014 as one of the top ten graduates in his training year and subsequently went on to become Head PGA Professional at Ryder Cup venue The Celtic Manor Resort. Equipment has always been a huge passion of Joe’s, and during his time at Celtic Manor, he headed up the National Fitting Centres for both Titleist and Taylormade. He’s excited to bring his knowledge of hardware to Golf Monthly in the form of equipment reviews and buying advice.

Joe lives in North Devon and still plays sporadically on the PGA West region circuit. His best round in recent years came earlier in 2023 where he managed a 9 under par 63 at Trevose GC in a Devon & Cornwall PGA Tournament.

Joe's current What's In The Bag?

Driver: Switch between TaylorMade Qi35 and Callaway Elyte TD - both with Fujikura Ventus Black 6-X

Fairway wood 1: TaylorMade BRNR Copper Mini Driver - Fujikura Ventus Black 7-X

Fairway wood 2: Callaway Apex UW 17˚- Fujikura Ventus Black 9-X

Irons: TaylorMade P7CB 3-PW with Dynamic Gold Tour Issue X100 shafts

Wedges: Callaway Opus 50, 54, and 60 degrees - Project X LS 6.0 shafts

Putter: LAB Golf Oz.1 (zero shaft lean)

Ball: TaylorMade 2024 TP5x

Grips: Golf Pride Tour Velvet 60R

Bag: Vessel Player IV Pro DXR Stand