Why Golf Pride And Pinehurst Is The Perfect Match

We visit the new Golf Pride HQ, now set in the vast golfing mecca that is Pinehurst Resort in North Carolina, to discover what goes on behind the scenes at golf's leading grip maker

Subscribe to the Golf Monthly newsletter to stay up to date with all the latest tour news, equipment news, reviews, head-to-heads and buyer’s guides from our team of experienced experts.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered daily

Daily Newsletter

Sign up for all the latest tour news, gear reviews, head-to-heads and buyer’s guides plus features, tips from our top 50 coaches and rules advice from our expert team.

Once a week

Kick Point

Sign up to our free Kick Point newsletter, filled with the latest gear reviews and expert advice as well as the best deals we spot each week.

Once a week

Women's Golf Edit

Sign up to our free newsletter, filled with news, features, tips and best buys surrounding the world of women’s golf. If you’re a female golfer, you won’t want to miss out!

Why Golf Pride And Pinehurst Is The Perfect Match

Underneath the towering pines of North Carolina, there lies a New England-style village that many regard as America’s Home of Golf. Pinehurst. Home to the famed No.2, a US Open venue on three occasions, Pinehurst’s history dates back well over a hundred years – and its archives boast some of the game’s most iconic moments, Payne Stewart’s winning putt at the 1999 US Open chief among them.

This is where the American golf story is rooted. In the early 1900s, James Walker Tufts, a wealthy businessman and the visionary behind the Pinehurst Resort, commissioned a young Scottish professional by the name of Donald Ross. In 1907, he created the No.2, and alongside Tufts, they went on to make Pinehurst the ultimate influencer of golf in America.

The Village of Pinehurst is not your typical village – it boasts nine golf courses, plus an 18-hole putting green and nine-hole short course. There are shops, restaurants, hotels and a host of activities on site. The United States Golf Association is building a second headquarters in Pinehurst, and the World Golf Hall of Fame is also upping sticks to base itself here. It’s a special place to play – we can attest to that – and not a bad place to work, either, as anyone at Golf Pride HQ will tell you.

For more than 50 years, the global leader in golf grip technology has been headquartered in the rural, sleepy Pinehurst/Southern Pines area. The company long thought about moving its headquarters to a more golf-centric location, a place like Carlsbad, California, which giants of the golf industry such as Callaway, TaylorMade and Titleist call home. Ultimately, it opted to partner with Pinehurst and be an integral part of the resort’s growth and move towards becoming the St Andrews of America.

The result is a new, 36,000 square foot facility that enhances collaboration and innovation while giving clues to the rich history of Pinehurst. Located less than 500 yards from the 1st tee of the No.8 course, it features ample R&D capabilities that help create the best golf grips, as well as a fitting studio that is open to the public and allows players to walk in and be fit for new grips. This Global Innovation Centre (GIC), as it’s known, is every bit the architectural masterpiece as Ross’ No.2.

Golf Pride President Jamie Ledford

“When we decided to plant our flag here, our pitch to the Pinehurst community was, ‘This might be the most unique place in the whole world,’” says Jamie Ledford, president of Golf Pride. “The number of golf courses that are within five minutes of us [there are approximately 40 in the area], and the number of people from around the world that are coming here on a constant basis... we just saw it as a steady stream of golfers flowing through regularly. All we had to do for our purposes was to just dip into that stream and pull a few out for testing every so often!”

Subscribe to the Golf Monthly newsletter to stay up to date with all the latest tour news, equipment news, reviews, head-to-heads and buyer’s guides from our team of experienced experts.

Thomas L Fawick, an industrialist and inventor from Cleveland, Ohio, founded Golf Pride in 1949. Fawick, a golf enthusiast, came upon the idea that rubber might be a superior alternative to leather for golf grips, by providing a more secure and durable gripping surface. It’s hard to believe now, but this was something of a lightbulb moment.

In 1953, the first ‘slip-on’ rubber grips arrived, which changed the lead-time and economics in manufacturing golf clubs, and made grip replacement a staple service in golf shops. Who remembers the iconic Green Victory grips? Fast- forward to today, and Golf Pride boasts 80 per cent usage at virtually every level of Major, professional and amateur competition.

Golf Pride has the most comprehensive range of grips on the market

No one at Golf Pride is resting on their laurels. The new state-of-the-art headquarters is a huge statement of intent. The grip category, says Ledford, remains an “emerging area of opportunity”, and there’s a lot of interesting work going on at the GIC – much of which is classified.

Given its location, in what can only be described as golfing paradise, it’s a wonder how staff get any work done, especially with a nine-hole putting course in the office, which, incidentally, runs at 16 on the stimp meter (we’re talking carpet, not grass... yet). However, you don’t get to a position of dominance without innovating – and this is where the magic happens.

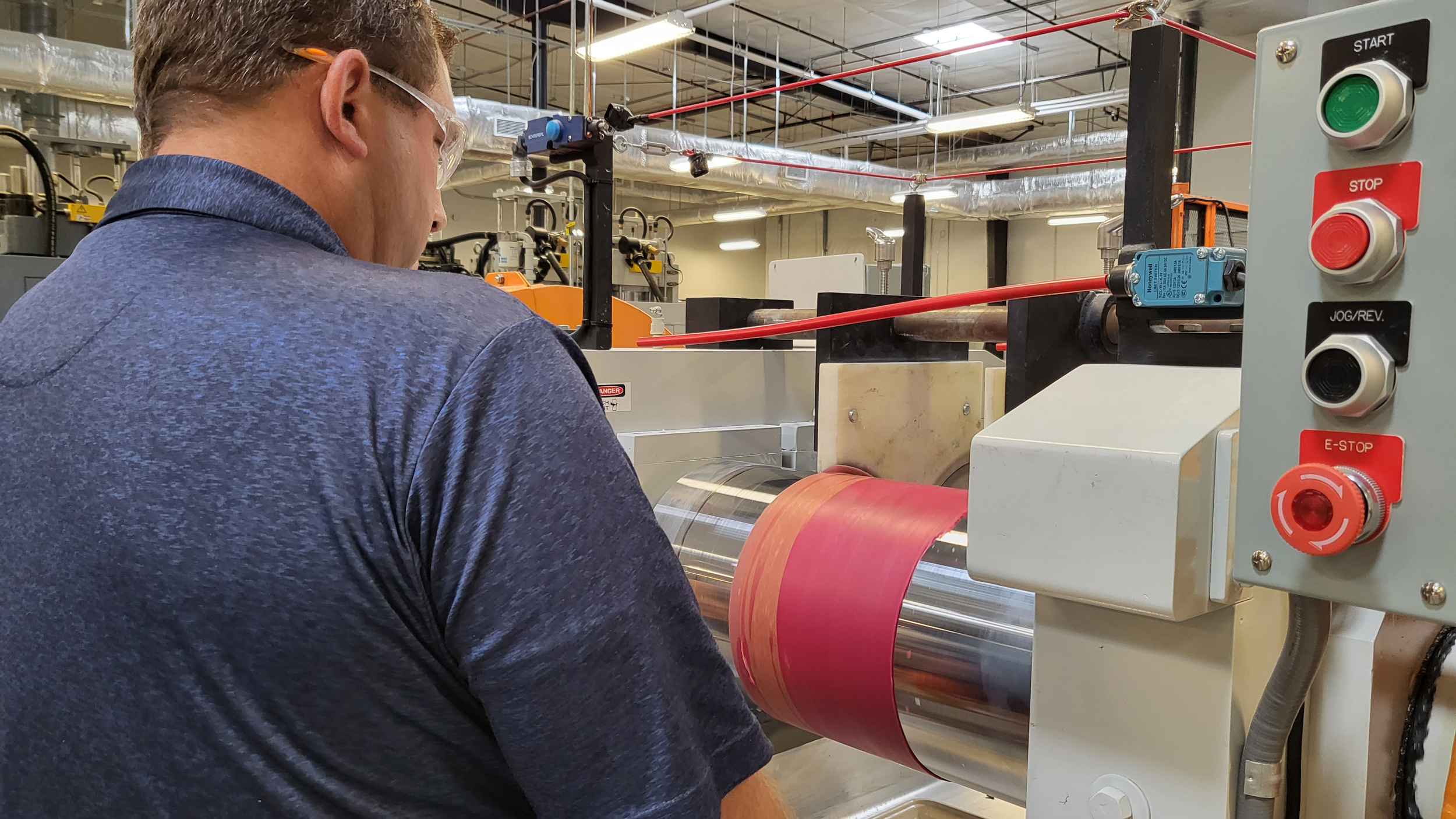

Every model in Golf Pride’s grip range has its own unique recipe and page upon page of ingredients. Greg Cavill, global project engineering manager – formerly of True Temper and known as one of the finest minds in the world of steel golf shafts – says grips are far more complex than most people realise. As well as manufacturing, developing and designing its own rubber compounds, Golf Pride develops its own tooling (parts and moulds used in the production of rubber grips). In short, bringing a new product to market can be a lengthy process – in the case of the new CPX grip, 24 months, although the Covid pandemic did stretch this time out a little.

“CPX went through so many iterations,” explains Cavill. “In actual fact, it was in a completely different product category to begin with. After interactions with the consumer, we were able to pinpoint where it needed to sit. We then went through rapid tool designs and kept developing the compounds to get to a point where we were ready to go.”

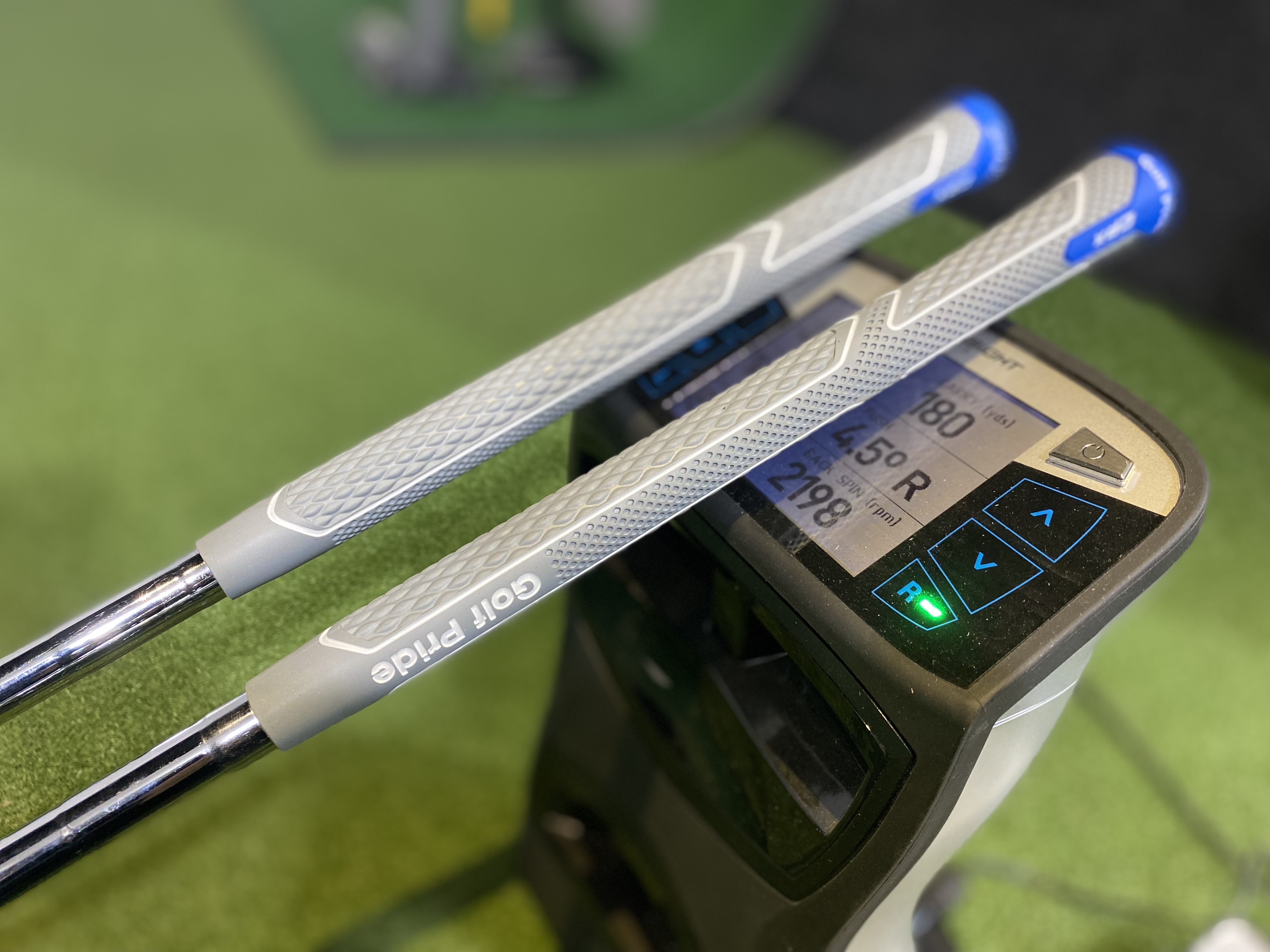

Sara Bryant, development engineer at Golf Pride, conducts grip testing and fitting at the in-house fitting studio. It’s a process she believes will provide value to golfers in time. At this stage, the journey has just started, as she’s only just beginning to collect the data that will identify tangible trends related to what can happen when playing the wrong-sized grips.

Much of the challenge revolves around capturing motion photography of how the hands work and interact with the grip during the swing, a daunting task given how biomechanically complex the hands are. Bryant, who has an academic background in biomechanics, says that golfers should rely on their on-course experiences to identify they have chosen the right golf grip. “If you’re out on the course and maybe seeing this or feeling this, that means that maybe [you’re] in the wrong size or the wrong material or the wrong family of grip,” she says. “That’s what I want to understand, so that I can give players the appropriate recommendation for their individual game.”

Bryant adds that she has seen some evidence that the wrong-size grip can result in dispersion inconsistencies. “I did a preliminary study [of grip size] and looked at our undersize, standard, midsize and jumbo grips, and just from a quick evaluation we were seeing some trends. Undersize was a little more left, jumbo was a little more right. It wasn’t statistically significant, so that’s something I want to explore to see what’s actually changing. Is that related to hand size? How is that actually changing? I know we have hand length, but is that the proper measurement?”

Being located at the heart of a golf community with access to a stream of passionate amateur golfers, many of whom are only too happy to participate in research, is extremely beneficial. Andy Erickson, director of global product innovation at Golf Pride, says the bulk of the time is spent working with Joe Public. However, tour players will always play a key role in grip development, too.

“I’m a big believer in learning from the extremes, the extremes being the best players in the world versus those who can’t play very well, or maybe play infrequently,” says Erickson. “The tour pros are super helpful when we get to that final stage of work. ‘Do we have something here?’ ‘What can you tell is different?’ They’re so dialled in, so they’re really helpful with that.”

Cavill tells an interesting story of the tour pro who, a few years back, said how he preferred getting his grips worn to the point where they actually get tackier. “Once we heard that, we spoke to our R&D team, explained what he needed, and were able to have prototypes turned around in 24 hours,” says Cavill.

“The player put that grip – now available to consumers as the Tour Velvet Align Tack – in play on the PGA Tour. We didn’t know that product was needed until we spoke to the player and heard what he was looking for. Direction comes from multiple sources.”

So what does the future hold for grips? Much has changed in the grip category over the last 70 years. However, Ledford says Golf Pride is only just getting started. You don’t build an Innovation Centre like Golf Pride has just for the sake of it.

“The grip category is still one of the most understudied and underdeveloped equipment categories,” says Ledford, who is keeping one or two research projects close to his chest. The future is a progression of the material science and consumer research, but can we expect another groundbreaking moment similar to Fawick’s ‘discovery’ of rubber?

“Rubber is a great material for grips, but we’re not at the end of the runway of great grips that we can design,” says Ledford. “As we go forward, we see ourselves chasing performance for golfers and then we need to let those designs dictate what materials we use, either for weight, durability, tack or texture. If there are better materials out there, we need to be able to chase them. We don’t just see ourselves as a rubber company; it’s still our core and where we started, but we’re going to look far and wide for anything that will work.”

One particular area of focus for Golf Pride is putter grips. Over the last decade, this category has changed significantly. Grips such as the Tour Snsr, which helps promote lighter grip pressure and better feel and feedback, are changing the way golfers see grips. More of us are starting to see the grip as equipment, rather than just handles – and this, Ledford says, is one of the company’s key goals.

“There are so many ways to miss a putt from about a foot,” he jokes. “We’ve been really focused on swing grip innovation because it’s our core, but we have more work to do when it comes to putter innovation. We’re not ready to share all of it, but it’s a good chunk of the grip research that we’re doing right now.

“We’re trying to find shapes and textures and other aspects of that grip that will help you get the ball in the hole. There are so many different design considerations we have to make – it’s still a club in your hands, but it’s such a different motion.”

Whatever discoveries come over the next year, five years, 20 years... they’re likely to be made in Pinehurst, and within the four walls – or hitting bay – of Golf Pride’s Global Innovation Centre. Should you ever be fortunate enough to visit the idyllic golf haven that is Pinehurst, be sure to stop by Golf Pride. You’ll never look at grips the same way again.

Michael has been with Golf Monthly since 2008. A multimedia journalist, he has also worked for The Football Association, where he created content to support the England football team, The FA Cup, London 2012, and FA Women's Super League. As content editor at Foremost Golf, Michael worked closely with golf's biggest equipment manufacturers and has developed an in-depth knowledge of this side of the industry. He's a regular contributor, covering instruction, equipment, travel and feature content. Michael has interviewed many of the game's biggest stars, including seven World No.1s, and has attended and reported on numerous Major Championships and Ryder Cups around the world. He's a member of Formby Golf Club in Merseyside, UK.