What Is An 'Aftermarket' Shaft And Do I Need One?

Gear expert Joe Ferguson looks into an area of the industry shrouded in mystery

If you have ever scrolled the websites of the major manufacturers and come across their custom options, you may be familiar with the term “aftermarket shaft”. So, what is an aftermarket shaft, and do you need one?

In basic terms, an aftermarket (or exotic as it is sometimes referred to) shaft is the highest quality, premium product a shaft company produces, created using its highest-grade materials and manufacturing processes. “Well, surely every manufacturer will produce the best product they are capable of every time?” you might ask. In reality, no, that is not the case. Many shaft manufacturers produce a cost-engineered version of their lines designed to be mass-produced for a specific club brand and end up in many cases being what we know as stock shafts.

Fujikura has a page of its website dedicated to highlighting its stock shaft partnerships with club manufacturers

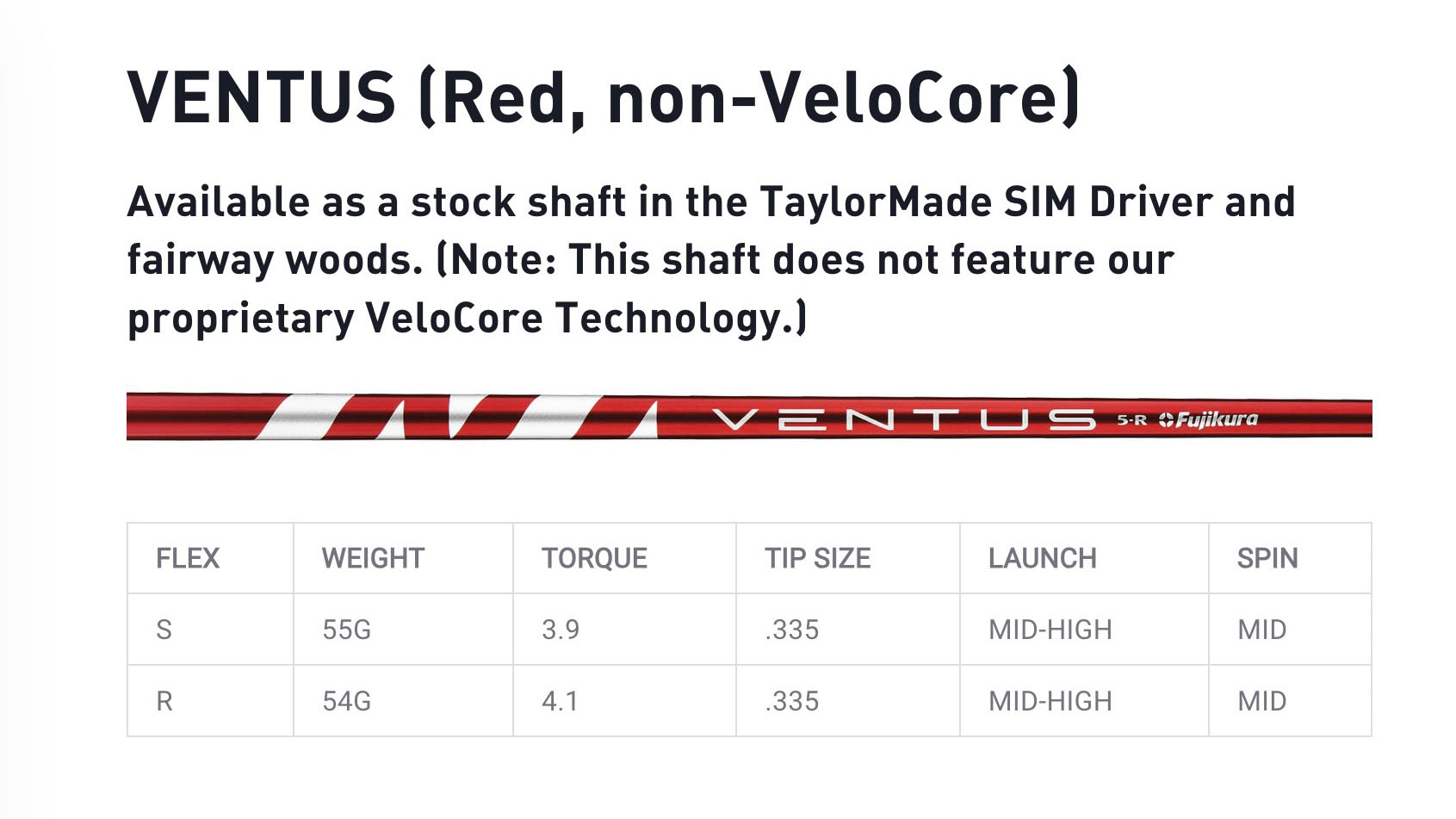

Stock shafts will often appear to be the same as their more expensive counterparts with the same graphics, fonts, and branding but may be missing certain features or technology. Take for example the Taylormade SIM driver. One of the stock offerings for this driver was the Fujikura Ventus Red shaft. Great, you might think, until you take a deeper look at the product. Whilst this stock product to all intents and purposes looks like the Ventus line you may have seen in the bags of tour professionals around the world such as Rory McIlroy and Scottie Scheffler, it is not. In this example, the stock Ventus shaft is missing the Velocore technology which is ultimately what has made the shaft so popular on tour. Velocore is a multi-material construction that reduces the ovalling of the shaft, producing more stability and as such consistency.

Rory Mcilroy is one of many tour players using the Fujikura Ventus Velocore shaft technology

So why do shaft manufacturers build these watered down versions of their products? It all boils down to simple economics and marketing. Aftermarket shafts are expensive, with many of the best driver shafts retailing for over $350 the numbers would simply not add up in terms of profitability to make them a viable standard option. Therefore club manufacturers will ask a shaft manufacturer to produce a more cost-effective version of a popular tour shaft. This will be achieved by using lower-grade materials and less expensive manufacturing processes. For example, many aftermarket shafts are hand-rolled in small batches, versus stock offerings that are created in bulk by an assembly line system.

The benefits of this work both ways. The club manufacturer is perceived to be using extremely high-quality, tour-validated shafts and the shaft manufacturer receives great marketing, getting their company name out into the market in thousands and thousands of products.

KBS is another shaft manufacturer with an extensive "aftermarket" line up

As for the question of whether you need an aftermarket shaft or not? This is a topic that stirs much debate across the industry with many believing that the perceived performance benefits of an aftermarket shaft do not outweigh the often hefty price tag. On the other side of the coin, some people will vehemently argue that if you are looking for optimal performance, then utilizing the best-grade equipment available to you is essential.

As a former club fitter, I am of the opinion that if you are a strong, high-speed player, you should at least consider looking into aftermarket shafts if you haven’t already. The higher-grade materials and added stability simply stand up to higher loads better, producing tighter results in terms of spin, strike pattern and dispersion. That is not to say that a slower swing player could not benefit from the added consistency of strike that an aftermarket shaft may produce. In my experience, however, the less load placed on the shaft, the less apparent the performance gains are.

Subscribe to the Golf Monthly newsletter to stay up to date with all the latest tour news, equipment news, reviews, head-to-heads and buyer’s guides from our team of experienced experts.

Like many equipment-related dilemmas, the best thing to do is test. Once you have seen the results, you will be better placed to put your own personal dollar value on any performance gains.

Joe has worked in the golf industry for nearly 20 years in a variety of roles. After a successful amateur career being involved in England squads at every age group, Joe completed his PGA degree qualification in 2014 as one of the top ten graduates in his training year and subsequently went on to become Head PGA Professional at Ryder Cup venue The Celtic Manor Resort. Equipment has always been a huge passion of Joe’s, and during his time at Celtic Manor, he headed up the National Fitting Centres for both Titleist and Taylormade. He’s excited to bring his knowledge of hardware to Golf Monthly in the form of equipment reviews and buying advice.

Joe lives in North Devon and still plays sporadically on the PGA West region circuit. His best round in recent years came earlier in 2023 where he managed a 9 under par 63 at Trevose GC in a Devon & Cornwall PGA Tournament.

Joe's current What's In The Bag?

Driver: Switch between TaylorMade Qi35 and Callaway Elyte TD - both with Fujikura Ventus Black 6-X

Fairway wood 1: TaylorMade BRNR Copper Mini Driver - Fujikura Ventus Black 7-X

Fairway wood 2: Callaway Apex UW 17˚- Fujikura Ventus Black 9-X

Irons: TaylorMade P7CB 3-PW with Dynamic Gold Tour Issue X100 shafts

Wedges: Callaway Opus 50, 54, and 60 degrees - Project X LS 6.0 shafts

Putter: LAB Golf Oz.1 (zero shaft lean)

Ball: TaylorMade 2024 TP5x

Grips: Golf Pride Tour Velvet 60R

Bag: Vessel Player IV Pro DXR Stand